Cables for Single Pair Ethernet: Where Are We Headed?

Which SPE solutions are preferable against existing communication standards? This article written by HELUKABEL, premium member in the SPE Industrial Partner Network. HELUKABEL addressed the same topic in a webinar of the SPE PIONEER SUMMIT.

Single Pair Ethernet (SPE) is seen as one of the most important trends shaping the future of industrial communication. Advantages of this new connection technology featuring only one conductor pair include high-speed data transmission, reduced space requirements and lower costs. But where will it be applied in the future, which cable types will be required, and how will SPE perform compared to existing communication standards? HELUKABEL addressed these questions in a webinar titled "Single Pair Ethernet Cabling", which took place as part of the "SPE Pioneer Summit" webinar series.

Currently, various communication systems can be found in the industrial environment, such as Profinet, CAT 5e and 6a, Industrial Ethernet or Ethercat. However, Single Pair Ethernet has the potential to replace these technologies in numerous applications - thanks to data transmission at gigabit speeds and a simultaneous power supply via only one wire pair. This smart, flexible, cost and space saving solution makes real-time communication possible down to the field level.

A basic prerequisite for the use of SPE is to have the right technical infrastructure in place - from terminals and plug connections to cabling. In order to make the changeover easier for manufacturers and users, the same cable classifications were defined for SPE as are already used for Profinet:

-

Type A: wires with solid wire for permanent installation

-

Type B: wires with stranded conductors for flexible applications or vibrations

-

Type C: wires with stranded conductors for high dynamic applications (such as drag chains)

-

Type R: torsion tested cables with stranded conductors for robotic applications

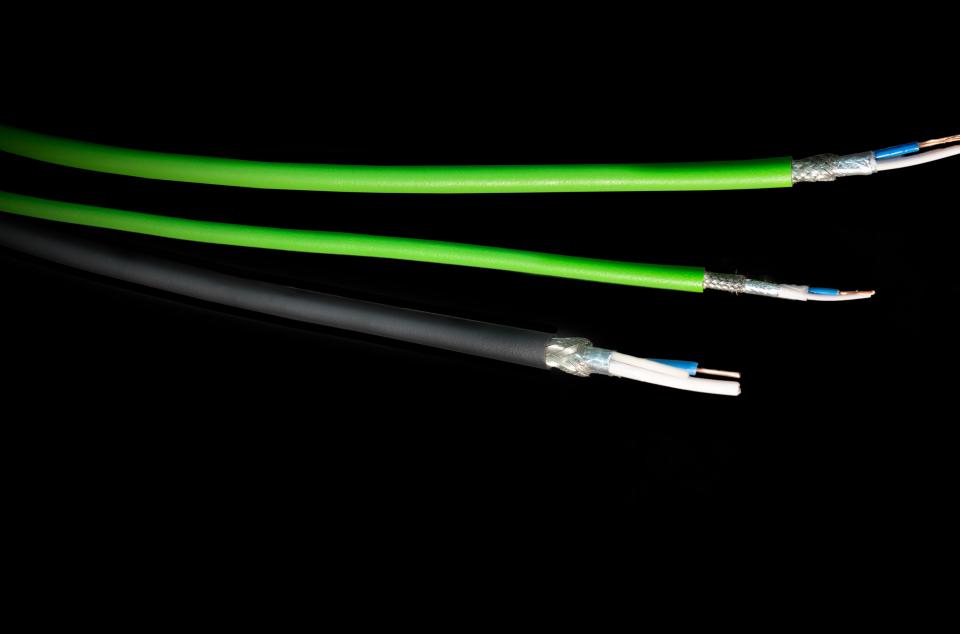

Drag chain and robot cables mainly differ by their respective screening designed for bending or torsional load capacity.

In addition, different sheath materials are used for each cable type to suit specific applications. Cables of type A and B are typically screened with PVC. There are also plenty of halogen-free, food safe and oil and chemical resistant alternatives to choose from. Type C cables are available in PUR, PVC and Santoprene, and type R robot cables are also available in PUR and Santoprene.